Automatic Carton Forming Inserting Sealing Machine

Summary

This automatic carton forming inserting & sealing machine is able to complete carton forming, carton inserting, carton folding, carton sealing etc. Available for individual operation, and able to connect with other machines for a complete packaging line. Good for packing fireworks, electronics, etc.

Feature

- Touch screen control with PLC system, automatically memory of setting data, digital operation, high working efficiency, save labor cost.

- Strong self inspection program with imported detecting electric eye, automatic alarm or stop running function for no raw materials, save production cost for the user, avoid unqualified product, and increase production efficiency.

- Made of stainless steel and high quality aluminum material, anti rust, easy cleaning.

- Good compatible for packing different products without changing any parts.

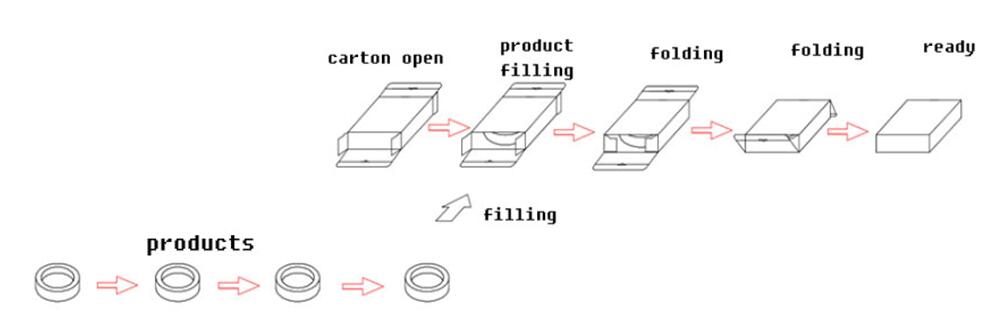

Flow chart

Controlling system

Colorful touch screen and PLC controlling system, simply setting and operation; microchip controlling, automatic alarm, machine stop functions, safe production and high efficiency; automatic counting function, control production schedule precisely. Automatic running after setting is done, save labor cost, cut off production cost.

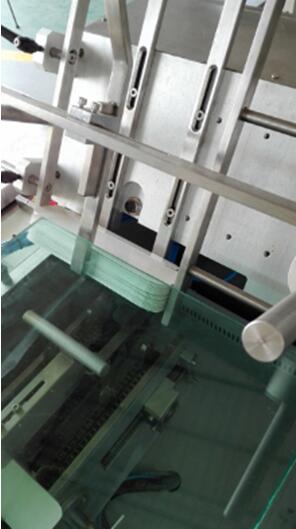

Carton sheet feeding system

Which for feeding carton sheet, it can hold 200-300 sheets each load. When running out of sheets, will require to upload manually. This system can be adjusted as per different sheet size.

Folding edge requirement for carton should be over 0.4mm deep, and carton should have pre-folded effect. Carton forming adopt vacuum chuck to suck the sheet up, and open the carton with well designed clamping apparatus, fix it on the conveyor, and automatic fill products into the carton.

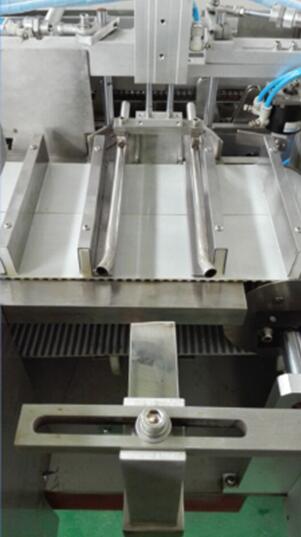

Products conveyor

Made of stainless steel, conform to food, medicine requirement standards, meeting GMP certificate requirement, widely applied to food, medicine industries. Conveyor cradle can be adjusted as different product size. Fast and convenient adjustment, simply operation. The cradle should be slightly larger the product size, but not too much. Products can be loaded manually for individual packing production, also available connect with other machine for automatic loading.

Product inserting system

Automatic controlling, accurate counting detective electric eye, no product, no opening; no carton no inserting; automatic detective and control, alarm, stop protection etc.

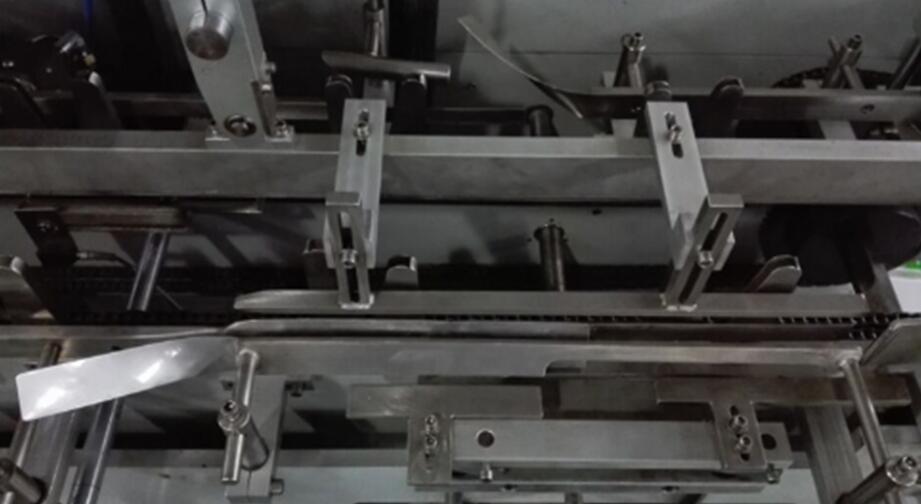

Sealing guiding rail

Well designed guiding rail for automatic carton folding and sealing. Mature mechanical structure, endurable performance, adjustment maintenance convenience. As per actual requirement, guiding rail for different products would be available for customer’s option. Changing rails for different products, fast and convenience.

Specification

|

Specification Details |

|

|

Inserting speed |

30-40 cartons per minute |

|

Carton range |

260 x 50 x 10mm or tailor designed |

|

Carton sheet loading quantity |

200-300 sheets per time |

|

Requirement of carton |

a/ folding imprint edge would be over 0.4mm and sheet should have pre-folded effect; b/ there should be 2-3mm space between products and the carton in directions of length, width and depth. |

|

Machine weight |

1.2T |

|

Dimension |

3000×1600×1650mm |

|

Rate power |

1.2Kw |

(Above data could be changed basing on actual production demand or technology improvement)